Solutions & Technologies

Our services for the client

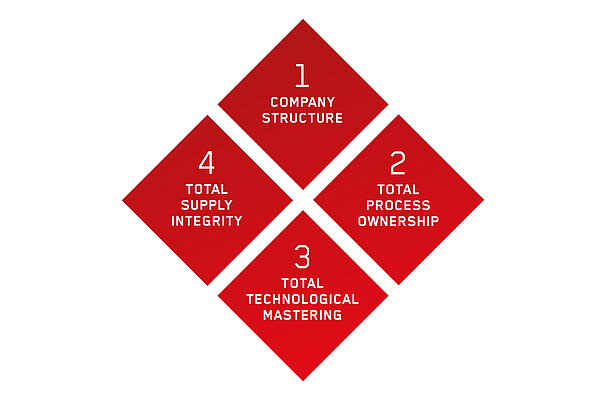

Our customer can choice to pick a full service range or only a single service step. We do not manufacture our own brands and are never in competition with our clients. Our state-of-the-art Development Center takes customers from dosage form design and formulation optimization to up-scaling and analytical method development.

The drug product moves into the transfer phase for optimization to large-scale processes and validation, including granulation and bulk manufacturing. We can then bulk-ship or package finished drug products for commercial distribution.

Together for safe pharmaceutical products

Quality Control

We provide all the analytical capabilities you need for outsourced manufacture and development of oral solid dosage forms.

Quality Assurance

We understand the increasing complexity of regulatory requirements.

Through our experienced Quality Assurance team we offer all required functions to always achieve full GMP compliance.

Qualified person

At Rottendorf Pharma we have several qualified persons who can approve our clients' products at any time.